Can aluminum alloy tankers replace steel tankers for oil transportation?

Time:2019-12-06

Views:1538

Can aluminum alloy tankers replace steel tankers for oil transportation? What are the technical characteristics of aluminum tank trucks?

The origin of aluminum tankers

Aluminum alloy tankers originated in the 1920s in Europe and America.

According to statistics, 7,000-10,000 transport vehicles in the United States use aluminum alloy materials each year. The European Union adds more than 40,000 vehicles each year. Oil products and powder particles are transported using aluminum alloy materials. In Japan, about 800- 1000 units, aluminum alloy materials accounted for more than 85%.

According to statistics, 7,000-10,000 transport vehicles in the United States use aluminum alloy materials each year. The European Union adds more than 40,000 vehicles each year. Oil products and powder particles are transported using aluminum alloy materials. In Japan, about 800- 1000 units, aluminum alloy materials accounted for more than 85%.

Steel tank trucks are only used in the field of pressure vessels or chemical liquid transportation. Because aluminum alloys have the advantages of collision-free sparks, no pollution to oil media, and light weight, they have been widely used in the field of refined oil transportation.

At the end of the 20th century, thanks to the entry of international oil companies such as BP and Shell into the Chinese market, the promotion of Yongqiang Automobile‘s cooperation with American Hair, the introduction of aluminum alloy tanker technology, and the rollout of China‘s first all-aluminum alloy tanker in 2001.

At the end of the 20th century, thanks to the entry of international oil companies such as BP and Shell into the Chinese market, the promotion of Yongqiang Automobile‘s cooperation with American Hair, the introduction of aluminum alloy tanker technology, and the rollout of China‘s first all-aluminum alloy tanker in 2001.

Characteristics of aluminum alloy materials

In terms of mechanical characteristics, aluminum alloy materials are lower than carbon steel products in terms of strength, hardness, and plasticity, especially in terms of fatigue resistance. It can be said that as long as stress concentration occurs, cracking will occur during use.

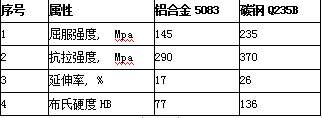

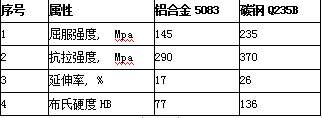

Table 1: Comparison of aluminum alloy materials and carbon steel materials

The mechanical index of aluminum alloy is lower than that of steel material, so more targeted adjustments need to be made on the structure. In order to ensure uniform stress distribution of aluminum alloy products and avoid stress concentration, linear design and overall frame structure should be preferred.

During the operation of the vehicle, the frame structure becomes a bridge for stress transmission, and the aluminum alloy sheet only bears the pressure of the liquid to ensure that the vehicle can effectively absorb the impact force in the event of an emergency.

Each frame structure is calculated according to different road conditions and transportation media. The surrounding structure must be able to bear twice the weight of the vehicle under full load to protect the tank top security parts from external forces.

Each frame structure is calculated according to different road conditions and transportation media. The surrounding structure must be able to bear twice the weight of the vehicle under full load to protect the tank top security parts from external forces.

Beware of excessive lightweighting

The overheating of lightweight indicators has also increased the risk of aluminum alloy tank trucks.

Since the promulgation of GB1589-2016, the 49T weight limit has been implemented nationwide. Aluminum alloy products are highly valued by customers for their superior lightweight indicators. Taking three-axle vehicles as an example, aluminum alloy transport tanker products are about 4 tons lighter than carbon steel. At the same time, lightweight indicators have become important indicators that manufacturers are vying for. In fact, the unrestricted pursuit of lightweighting also lays down security risks for later operations.

Since the promulgation of GB1589-2016, the 49T weight limit has been implemented nationwide. Aluminum alloy products are highly valued by customers for their superior lightweight indicators. Taking three-axle vehicles as an example, aluminum alloy transport tanker products are about 4 tons lighter than carbon steel. At the same time, lightweight indicators have become important indicators that manufacturers are vying for. In fact, the unrestricted pursuit of lightweighting also lays down security risks for later operations.

.png)

.png)