Bottom loading series of fuel tanker trucks and trailers

Instructions for use of European standard bottom loading series on Chengli oil tanker :

Vapor recovery: Vapor recovery valve is a device for recovering vapor generated during loading and unloading of oil. It can be installed directly on the tank top of the tanker or on the manhole cover. The rod and the subsea valve at the bottom of the tank can be opened in mechanical linkage, and the opening and closing can also be controlled by the air source.

Oil and gas recovery joint: The oil and gas recovery system of the oil station is composed of a fire-stop breathing valve, a pipeline flame arrestor, a three-way float valve, an oil and gas recovery joint, and a quick joint for oil and gas recovery. It forms a closed circulation system with the oil and gas recovery system of a tanker, which effectively The oil and gas generated in the process of refueling at the petrol station is recovered and reused to avoid the diffusion of oil and gas.

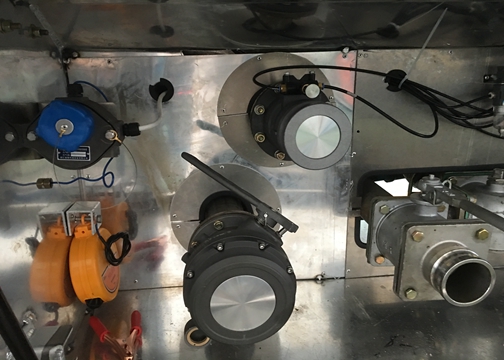

Submarine valve: The submarine valve, also known as the emergency shut-off valve, is installed at the bottom of the tank and used when loading and refueling. It is easy to operate, save time, and is safe and environmentally friendly.

Pressure-balanced subsea valves are used for multi-storage tank trucks, and can be loaded and unloaded separately from different tanks. The three-way design simplifies the pipeline, reduces the load, and is simple to operate, safe and reliable.

Bottom loading valve: The bottom loading valve, also known as the oil unloading valve, is installed under the side of the tanker for quick oil unloading.

Anti-overflow probe purpose: The anti-overflow electronic sensor is widely used in all kinds of containers and tanks when they are filled with liquid, a safety device to prevent liquid from overflowing and giving an alarm in advance. It is installed in the top manhole of the container Cover, when the oil level reaches the warning limit, the sensor will automatically alarm and switch off.

European standard tank cover: also known as manhole cover, installed on the top of the tank, with built-in breathing and emergency exhaust functions, and can be installed on the manhole cover with oil vapor recovery valve, oil metering hole, anti-overflow probe, etc. When the anti-overflow sensor system is in the process of filling oil, when the liquid level reaches the detection position, the sensor system will automatically alarm to stop filling the oil. The built-in breathing valve keeps the internal pressure of the tank truck stable during the oil transportation process, and balances with the external pressure. Its dumping prevention design makes the tank truck in

In the event of an accident, the emergency exhaust device will automatically open and release the pressure in the tank when the pressure in the tank rises sharply, thereby preventing accidents and greatly improving the safety of oil transportation.

.png)

.png)